- PIPES

- SS, DSS & HIGH ALLOY

- API 5L certified

- Line pipes,Casing and Tubing

- Coiled Tubing

- Sizes

- Material

Type of Pipes Size mm Size Inches Wall Thickness Seamless 6 – 630 mm 1/4′ – 24″ 0.5 to 32 mm Hot Finished 51 – 219 mm 2″ – 8 1/2″ 6 to 32 mm Welded 6 – 2000 mm 1/4″ – 78″ 0.5 to 65 mm Sl. No. Materials Typical Grades 1 Austenitic 304/L/H, 316/L/Ti, 321/H, 317L, 347H, 310S/H 2 Super Austenitic 904L, 6Mo(S31254), S30432, S31042 3 Duplex S32001, S32304, S31500, S31803, S32205 4 Super Duplex S32750, S32760, SUS329J4L 5 Corrosion resistant/ High temperature resistant Alloys N06600, N06985, N08028, N08800, N08825, N04404, N04405, N010276 6 PH Stainless Steel 17-4PH, 15-5PH 7 Ferritic 409L, 439 - LSAW

- API 5L certified

- Grade up to API 5L X80-PSL2 and ISO 3183 from L245 to L555

- Offshore and Onshore pipelines

- Diameter from 20” to 120”

- Wall thickness upto 60mm

- Pipes can be coated in same mill as per client requirements internally and externally.

- HSAW

- API 5L certified

- Up to X80 Grade

- The range comprises from 18” to 130” dia with wall thickness from 6mm to 25mm

- Faster delivery

- SEAMLESS

- API 5L/5CT

- Line Pipes, Casing and Tubing.

- Sizes upto 14” (355.60mm) O.D. bevelled, plain or threaded ends.

- Casing and Tubings upto 13 3/8” (339.72 mm)OD plain or threaded end and coupled with API round threads (STC or LTC) or Buttress threads (BTC)

- Quick delivery

- Coating as per client requirements

- ERW

- API 5L/5CT

- Line Pipes, Casing and Tubing.

- Sizes upto 20” O.D. bevelled, plain or threaded ends.

- Upto X70 Grade

- Casing and Tubings upto 20” OD plain or threaded end and coupled with API round threads (STC or LTC) or Buttress threads (BTC)

- Quick delivery

- Coating as per client requirements

- GRE/ FRP

- API 15HR certified

- Pipe diameter 1 ½” to 24”

- Pressure rating 3.5 Mpa to 25 Mpa

- Anhydride cured pipes

- Amine cured pipes

- Working temperature 115 deg C.

- Down hole Casing and Tubing

- Corrosion resistance

- High strength and light weight

- Long service life

- COMPOSITE/RTP

- High fatigue and chemical resistance

- Spoolable

- Coiled tubing

- Can be used for Cryogenic application

- Includes permeation barrier

- Dimentions up to 6” OD

- Materials used are PVDF, PP and PE

- Long service life

- One material concept, reinforcing liner with fibre-tapes creating one stable wall for high pressure ratings

- Higher allowable strain: spoolable without fatigue and without cracks

- Higher ductility resulting in unsurpassed toughness, impact resistance and residual strength

- Minimized risk of liner buckling resulting in optimal gas decompression resistance

- Weldable, thermoplastic tubulars can be connected through welding

- Suitable for high pressures and pressure fluctuations

- High allowable strain: spoolable without fatigue and without cracks

- Higher ductility resulting in unsurpassed toughness, impact resistance and residual strength

- No risk of liner buckling avoiding rapid gas decompression issues

- Low friction

- Light weight

- PIPE COATINGS

- Anticorrosion coating as per international standards.

- Special corrosion resistant coating to withstand 120 deg C temperature

- External 3LPE, 3LPP coating

- Internal liquid epoxy coating(ATF, Oil & Gas, Slurry and portable drinking water )

- External coal tar enamel/ bitumen coating

- Weight concrete coating for subsea pipelines and river crossings.

- Cement lining internally and externally.

- Field weld coating for external and internal girth weld joints for onshore and offshore pipeline projects.

- VALVES

- CONTROL VALVES :

Control valves are valves used to control conditions such as flow, pressure, temperature, and liquid level by fully or partially opening or closing in response to signals received from controllers that compare a “setpoint” to a “process variable” whose value is provided by sensors that monitor changes in such conditions. The opening or closing of control valves is done by means of Electric, Hydraulic or Pneumatic systems. We can supply control valves as per customer requirements with different sizes, pressure class with all material range such as Carbon Steel, Stainless Steel, Duplex Stainless Steel, Super Duplex Stainless Steel, Aluminium Bronze, Copper Alloy, Incoloy. Ball, Globe and Butterfly type control valves as per client requirements.

- ESD/MOV/ IPF VALVES : Valves as per client requirements in different sizes, Electrically, Hyaudraulicaly, Pneumatically operated actuators with all accessories.

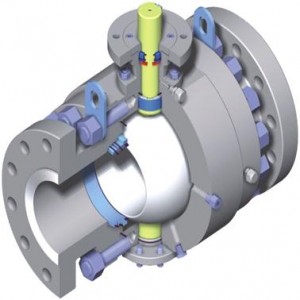

- BALL VALVES:

- Metal seated ball valves for steam applications.

- Soft seated ball valves.

- AS PER ISO, API, BS standards with Flanged, BW, FNPT, and Socket welded ends.

- Size ¼” to 80”

- Pressure class upto ANSI 2500

- Material: Alloy cladded, FBE coated internally, Carbon Steel, Stainless Steel, Duplex Steel, Super Duplex Steel, Aluminium Bronze, Copper Alloy, Incoloy

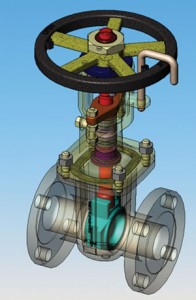

- GATE VALVES:

- AS PER ISO, API, BS standards with Flanged, BW, FNPT, and Socket welded ends.

- Size ¼” to 60”

- Pressure class upto ANSI 2500

- Material: Alloy cladded, Carbon Steel, Stainless Steel, Duplex Steel, Super Duplex Steel, Aluminium Bronze, Copper Alloy, Incoloy

- GLOBE VALVES:

- AS PER ISO, API, BS standards with Flanged, BW, FNPT, and Socket welded ends.

- Size ¼” to 36”

- Pressure class upto ANSI 2500

- Material: Alloy cladded, Carbon Steel, Stainless Steel, Duplex Steel, Super Duplex Steel, Aluminium Bronze, Copper Alloy, Incoloy

- CHECK VALVES :

- High lifting Check valves, Swing Check valves, Dual Plate Wafer/ Wafer lug/ flanged Check valves.

- As per ISO, API, BS standards with Flanged, BW, FNPT, and Socket welded ends.

- Size ¼” to 80”

- Pressure class upto ANSI 2500

- Material: Alloy cladded, Carbon Steel, Stainless Steel, Duplex Steel, Super Duplex Steel, Aluminium Bronze, Copper Alloy, Incoloy.

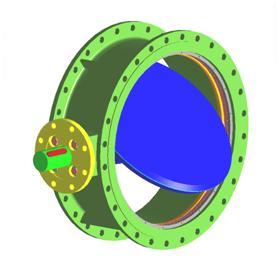

- BUTTERFLY VALVES

- As per ISO, API, BS standards with Flanged, BW, FNPT, Socket welded ends.

- Size ¼” to 80”

- Pressure class upto ANSI 2500

- Material: Alloy cladded, Carbon Steel, Stainless Steel, Duplex Steel, Super Duplex Steel, Aluminium Bronze, Copper Alloy, Incoloy.

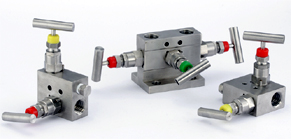

- INSTRUMENTATION VALVES

- Monoflange valves, Slimline valve, Single Block and Double Block valves as per client requirements.

- Size ¼” to 3” and pressure class upto 2500#

- Needle valves from ¼” to 2” sizes with 10,000 PSI pressure.

- Material : Carbon Steel, Low Temperature Carbon Steel,, Stainless Steel, Duplex & Super Duplex steel, Alloy steel etc.

- End connections Flanged, FNPT etc.

- HEAT SHRINK SLEEVES

- 3 Layer Heat Shrinkable Sleeve- HSS series

- 2 Layer Heat Shrinkable Sleeve- HCS series

- Mastic Heat Shrinkable Sleeve- HMS series

- Direct Drill coating protection Sleeve – HRSS

- Heat Shrinkable Wrap-around Tape- HCWT, HIWT

- PE Coating repair material

- Epoxy Primer series

- FLANGES & PIPE FITTINGS

Type of Fitting Sizes Materials Flanges 1/4″ TO 100″ Carbon steel, Stainless steel, Duplex stainless steel, Super Duplex stainless steel, Aluminum Bronze, Nickel Alloys, Titanium alloys and other exotic materials. Spectacle Blinds 1/4″ TO 48″ ELBOW/BENDS 1/4″ TO 72″ Reducers 1/4″ to 72″ TEE 1/4″ to 72″ Induction Bends 2″ to 48″ With bending angle from 0 to 180 Deg and bending radius upto 6100 mm; as per client requirements. Bends confirms with the API5L - SACRIFICAL ANODES

- Sacrificial Anodes for offshore structures.

- Sacrificial Anodes for Sub sea pipelines.

- Cathodic protection

- Custom designed as per client requirements

- CONTROL VALVES :