Equipments

- PRESSURE VESSELS & FUEL TANKS

- Heavy wall thickness pressure vessels of upto 120mm wall thickness.

- Size upto dia 10,000 mm

- Material of construction: CS, SS, DSS, TI,NI, INCOLOY, MONEL, HASTALLOY, CLADDED etc.

- Complies with ASME U stampings, U2 stamping as per ASME-Sec VIII, Div-2 and ISO 9001 Quality Assurance.

- Tanks as per API 650/BSEN-14015

- Good engineering practices for atmospheric vessels/ tanks.

- HEAT EXCHANGERS

- Falling film type H.E.

- Jacket Pipe reactor

- Condenser

- Bimetal tube double tube sheet H.E.

- High pressure coolers

- Maximum dimension in mm dia 2,700 x 19,500

- Materials of construction: CS, SS, DSS, TI,NI, INCOLOY, MONEL, HASTALLOY, CLADDED etc.

- Complies with ASME U stampings and ISO 9001 Quality Assurance

- Design as per TEMA, ASME

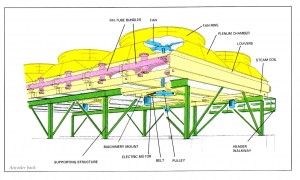

- AIR COOLED HEAT EXCHANGERS

- In collaboration with our world renowned principal we can supply Air Cooled Heat Exchangers as per customer requirements.

- Forced draft or induced draft type installations.

- Plug type and cover type headers.

- Products meet the requirements of ASME, API and HTRI and authorised to use these logos.

- Finned tubes types include G embedded, L wrap, Knurled l fins, Bimetallic extruded fins.

- Largely used in Oil & Gas industry, Refineries, Chemical Plants, Fertilizer Industries, Steel, Power Plants and Process Industries.

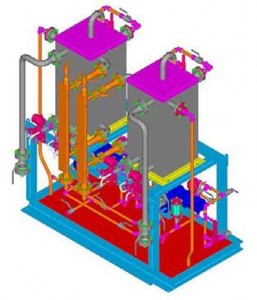

- CHEMICAL INJECTION SKIDS

- Chemical Injection Skids can be designed and built to meet any application, pressure, standards and specifications (including Conventional types, Multi Well/Multi Injection, Solar Powered, PLC based etc.).

- Application: Chemical agents employed in field processing include drilling fluid additives, Methanol injection for reservoir stimulation, Glycol injection for hydrate inhibition, produced water treatment chemicals, foam and corrosion inhibitors, de-emulsifiers, desalting chemicals and drag reduction agents (DRAs). Chemicals are frequently administered by way of chemical injection skids.

- COLUMNS

- Rectification columns

- Dehydration column

- Distillation column

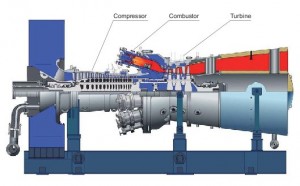

- GAS TURBINES

- 25 MW, 15 MW (ISO Capacity) capacities.

- Heavy duty

- Easy to maintain

- Commitment to delivery and quality

- High efficiency

- High reliability

- Strong Middle East presence with sufficient experience in Middle East.

- Low emission level

- Long maintenance interval and less maintenance cost

- Dual fuel capability

- LO-NOx burners

- NOx Suppression with Water/Steam injection.